A professional tool&die maker for big progressive tools and transfer tools

From Zerostart to Unlimited Cooperation

Focus on Stamping tool&dies

The rapid development of metal stamping molds in China's mold manufacturing industry requires strict technical research and production quality control. It has gradually moved towards a large-scale development trend. Hardware stamping molds are widely used in various industries. Below, I will share the feature classification of hardware stamping molds with you.

The rapid development of metal stamping molds in China's mold manufacturing industry requires strict technical research and production quality control. It has gradually moved towards a large-scale development trend. Hardware stamping molds are widely used in various industries. Below, I will share the feature classification of hardware stamping molds with you.

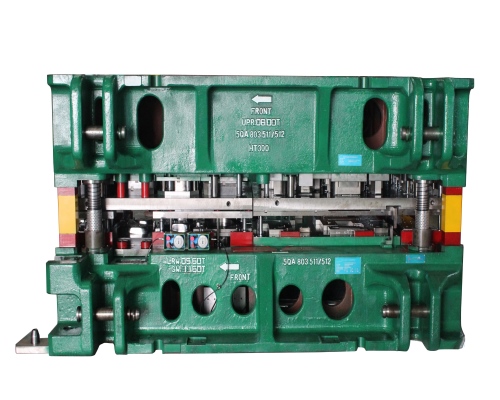

Hardware stamping mold

Hardware stamping molds can be divided into three categories according to different characteristics

1: According to the deformation characteristics of materials, they are classified into blanking molds, punching molds, cutting molds, cutting molds, edge cutting molds, bending molds, drawing molds, forming molds, embossing molds, cold extrusion molds, etc.

2: According to the nature of the process, there are punching dies, bending dies, drawing dies, and forming dies. A die that separates materials along a closed or open contour line. A mold that causes bending deformation of blank or other blank materials along a straight line (bending curve), thereby obtaining a workpiece with a certain angle and shape.

3: According to the degree of process combination, there are single process molds, composite molds, and progressive molds. A mold that completes only one stamping process in one stroke of a press. The composite mold has only one workstation, and in one stroke of the press, it is a mold that completes two or more stamping processes simultaneously on the same workstation.

Progressive molds (also known as continuous molds) have two or more workstations in the direction of blank feeding. They complete two or more stamping processes on different workstations in one stroke of the press.

The materials used for manufacturing metal stamping molds include steel, hard alloys, steel bonded hard alloys, zinc based alloys, low melting point alloys, aluminum bronze, polymer materials, and so on. At present, most of the materials used to manufacture stamping dies are steel. The commonly used materials for working parts of dies are: carbon Tool steel, low alloy Tool steel, high carbon high chromium or medium chromium Tool steel, medium carbon alloy steel, high-speed steel, base steel, hard alloy, steel bonded hard alloy, etc.

info@zerostart-tool.com

No.525,Jinxing Road FuShan Village LiaoBu Town,DongGuan city,GuangDong Province,China

(86-769)81008391

Online service

Website QR Code