A professional tool&die maker for big progressive tools and transfer tools

From Zerostart to Unlimited Cooperation

Focus on Stamping tool&dies

The process plan for determining the winding parts in a stamping factory is to determine the placement of multiple winding processes and the mold layout for each process. To reasonably determine the winding process plan, it is necessary to first master the commonly used winding mold layout and working principles, and then determine the process plan and process placement based on the mold layout, working principles, and characteristics.

Electronic stamping products have their peculiar characteristics in daily processing:

1. The number of processes in electronic stamping parts processing is related to the properties of the material, stretching height, stretching path, pulling diameter, material thickness, and other prerequisites;

2. The flushing process for electronic stamping parts includes chemical flushing methods such as alkaline solution flushing, solvent flushing, and surfactant flushing;

3. The adhesion between the coating and the substrate of electronic stamping parts is the link to ensure the quality of electroplating products. Before electroplating, there will be various kinds of dirt on the surface of the substrate materials, such as (Cutting fluid, lubricating fluid, polishing paste, etc.). The cleanliness of the substrate surface directly affects the adhesion of the electroplating layer, and surfaces with oil stains must be rinsed.

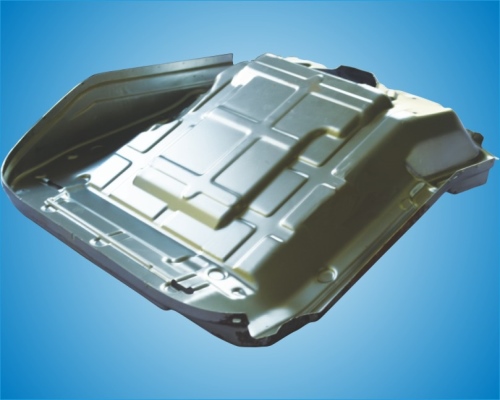

Electronic stamping products

Electronic stamping parts are mostly used in multifunctional digital or household appliances. Due to the relatively small size of the parts, what should we pay attention to when forming?

1. The internal R arc in the forming position of electronic stamping parts should not be too large, as it not only undergoes plastic deformation but also elastic deformation. If the internal R is large, the rebound increases and cannot ensure the consolidation of the forming angle;

2. The circular arc of the forming punch should not be too small. If the forming angle of the punch is small, it is easy to scratch the outer side of the material. For ordinary soft materials, it is very low at twice T, and for hard materials, it cannot be lower than 1.5-2T;

3. The formed straight edge cannot be too short. In order to ensure the relationship between the forming position and angle consolidation of electronic stamping parts, although the formed straight section is made high, it should not be lower than 2T when it is very low;

4. If the position of the forming and the hole is relatively close, in order to ensure that the hole is not easily deformed and also ensures accuracy, although it needs to comply with the relationship between the forming inner fillet r and the plate thickness t (t<2, 1 ≥ r+t; t ≥ 2, 1 ≥ r+2t)

info@zerostart-tool.com

No.525,Jinxing Road FuShan Village LiaoBu Town,DongGuan city,GuangDong Province,China

(86-769)81008391

Online service

Website QR Code